Introduction

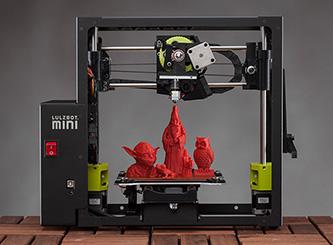

3D Printers3d printers is a modern printing device.this modern machine print almost everything which you want,like your shoes,your box,yours new house model ,that is you proposed in your mind,you print in real world. To print 3D object by 3D printer to use some specific materials such as plastic and metal .Using different 3D printing technologies and materials you can print with, but all are based on the same principle: a digital model is turned into a solid three-dimensional physical object by adding material layer by layer.the material is simply heated up until it becomes soft so that it can be molded into something that you want.The printing can take much more hours to complete printing,it is depending on the size of modal, and the printed objects are often post-processed to reach the desired finish.

If you want 3D printing or 3D printers, now it necessary to know what is new technology use in 3D printer. This will help you understand and grow your business or hobby .

3D Printing Technologies

Now days in 3D printing use many technologies,so we suggest you firstly Identifying your unique requirements within the entire design-to-manufacture process will help you select the best 3D printing technology and optimize its benefits.here we declared some technologies form

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Vacuum Casting (RTV)

- Investment Casting

- Preparing 3D models

- Preparing your 3D models for printing

Some of the more common applications where use 3D printer.

1. Functional Testing- To check how to work proposed machine that design by engineers to use in near future it is always made up plastic and metal parts and assemblies before preparing checking machine function.

2. Presentation Models- when any engineer or student create new modal ,then need to representing at community or team ,whit this create interactive models to marketability and quality full presentation to show every one.

3. Casting Patterns- create impressions and cavities in temporary tooling to secondarily cast or mold plastic or metal parts of 3D solid models.

4. Production Parts- Production of end-use plastic and metal components that use to directly in market place.

Stereolithography Models

Always minimize wall thickness and solid sections as much as you want. it will reduce the volume of material used, and in turn, reduce cost.Some CAD data. comprises a skin with no actual thickness. it will give you a falsely low material volume calculation and an incorrect estimate or quote.

Stereolithography resin is hygroscopic. If your models will be in contact with fluids or used in a humid environment, please contact us for advice on sealing the surfaces of the stereolithography models.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a solid-based rapid prototyping method that extrudes material, layer-by-layer, to build a model. The key advantage FDM is that it is ideal for Conceptual Models, Engineering Models, and Functional Testing Prototypes.

Selective Laser Sintering (SLS)

The selective laser sintering technology uses a CO2 laser to sinter (fuse) a variety of thermoplastic and metal powders to "grow" 3D objects.layer-by-layer from 3D electronic data (STL files). Because this is an additive process, highly complex geometries can be built without issue, and because the powder holds the parts, no support structures have to be added and removed. The key advantage of laser sintering is its ability to rapidly produce durable, functional objects for a wide variety of applications.

Using 3D printing

3D printer use any one but mostly use of industry or profession persons. we describe some common examples to show how people use 3D printing and printer.

- CAR MANUFACTURERS

- DOCTORS

- DENTISTS

- PROSTHETICS

- AIRCRAFT MANUFACTURERS

- AEROSPACE COMPANIES

- PROP MAKERS

- PRODUCT DESIGNERS

- ARCHITECTS

- STUDENTS

- DESIGN ENTREPRENEURS

- ENGINEERS

- DRONE ENTHUSIASTS

- SHOE MANUFACTURERS

- CONSUMER PRODUCT MAKERS

Mostly Use 3D Printing Materials

- plastic

- metals

- ceramic

- gold

- silver

- titanium

- gypsum

- biological substances.

Mostly created product by 3D printers

- Biological substances ( ear and a jaw,artificial heart, kidney etc..)

- dresses

- shoes

- drones

- bicycles

- vehicles

- House use products

Now can say you start 3D printing and make good presentation and make new products and achieve your life target,grow society and grow humanity.

0 comments:

Post a Comment